The age of humanoid robots is no longer speculative—it’s being built today. At automatica 2025 in Munich, manufacturers and research institutes from around the globe revealed the current state of humanoid development, with applications spanning logistics, healthcare, education, and industrial automation. With China and the U.S. leading the race and Europe pushing forward via collaboration, the humanoid sector is set for exponential growth.

Humanoids on the Move: China’s Public Show of Strength

One of the most symbolic events was a half marathon in Beijing, where nearly 20 Chinese humanoid robots successfully competed alongside humans across a 21-kilometer course. The stunt showcased China’s push to be the world’s top supplier of humanoid machines. According to industry plans, 5% of China’s workforce—about 35 million roles—could be augmented or replaced by humanoids in the coming years.

Companies like Unitree, AgiBot, Engine AI, Fourier, and Ubtech are already deploying units across sectors. The Unitree G1, a 1.3-meter, 35-kg humanoid, is available at a groundbreaking price of €16,000 in China (approx. €30,000 in Europe). Despite the cost, demand is high across academic and industrial users.

U.S. Leads with Capital and Capability

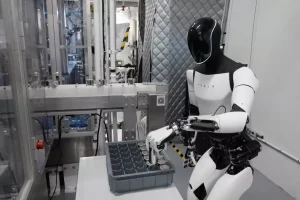

Humanoid development in the United States is led by giants like Boston Dynamics (Atlas), Tesla (Optimus), Figure AI (Figure 01, 02), and Apptronik (Apollo)—all of which are now engaged in real-world pilot programs with manufacturers such as Mercedes-Benz and GXO Logistics.

Agility Robotics, maker of the bipedal Digit, is already operating in Amazon’s logistics centers. Digit can lift up to 16 kg, navigate autonomously via LIDAR and cameras, and handle variable tasks in complex environments. Melonee Wise, Agility’s CPO, and Carolin Richter of BMW shared deployment insights at the automatica Forum in Hall A5.

Apptronik, backed by Google DeepMind, NVIDIA, and NASA, recently secured $350M in funding to maintain its edge in scalable humanoid development.

Germany’s Emerging Role and Strategic Collaborations

Germany’s Emerging Role and Strategic Collaborations

While Germany lags in global rankings, it presented notable innovations at automatica. Neura Robotics’ 4NE-1, introduced in 2023, was joined by Igus’ Iggy Rob, a €50,000 humanoid assembled from in-house ReBeL cobot components. Igus plans to use Iggy Rob internally for injection molding automation, while also promoting it for education and industrial training.

A promising highlight was the exhibit by the German Aerospace Center’s Institute for Robotics and Mechatronics, which announced a strategic collaboration with Siemens. “This partnership exemplifies how aerospace tech can benefit industrial robotics,” said Institute Director Alin Albu-Schäffer, adding that such alliances are crucial for ensuring Europe’s competitiveness.

Why Legs Matter: Beyond the Wheels

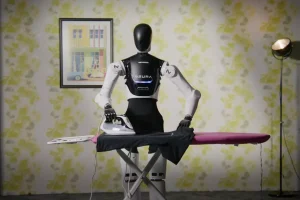

Why build bipedal robots? Jonathan Hurst, CRO of Agility Robotics, explained that two-legged humanoids offer greater environmental adaptability than wheeled models. They can climb stairs, navigate curbs, and mimic human actions—making them more versatile in real-world settings. This makes humanoids especially attractive in fields like warehousing, healthcare, and domestic assistance.

A Market Ready to Explode

A Market Ready to Explode

Global projections place the humanoid robot market at $38 billion by 2035, according to Goldman Sachs. Elon Musk’s Optimus is positioned not just for industrial work but eventually domestic applications like childcare and elderly care.

Backed by massive state and private investments, China aims to dominate the global humanoid market within three years—while the U.S. continues to innovate rapidly through high-tech partnerships. Germany, though trailing, is making strategic bets on affordability and industrial integration.

Automatica 2025: Where the Future Takes Shape

From ultra-low-cost Chinese humanoids to NASA-grade American robotics and Germany’s tech transfer from aerospace to the shop floor, automatica 2025 confirmed that the future of automation is human-shaped. With advancements in AI, energy systems, and motion mechanics, humanoids are no longer lab prototypes—they’re ready for work.