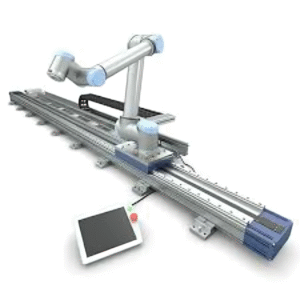

Collaborative robots, or cobots, are increasingly becoming integral to modern manufacturing. One critical performance metric that determines their efficiency is axis speed — the maximum rotational or linear velocity that each robotic joint can achieve. This parameter directly impacts productivity, safety, and application flexibility.

What Is Cobot Axis Speed?

Axis speed refers to the motion capability of each individual joint in a robot’s arm. Larger, load-bearing joints like the base rotate more slowly for stability, while smaller joints, such as the wrist, can move with exceptional speed.

-

Measured in:

- Degrees per second (°/s) for rotational joints

- Millimetres per second (mm/s) for linear axes

Key Factors Influencing Speed

Several elements determine a cobot’s maximum axis speed:

- Axis Size Variation: Larger joints are slower; smaller joints are quicker.

- Payload Weight: Heavier loads reduce movement speed.

- Safety Considerations: Human-robot interaction limits are imposed for workplace safety.

- Application Customisation: Speed settings can be adjusted for specific operational needs.

Industry Examples (5–6 kg Payload Range)

Notable cobots in this performance category include:

- TECHMAN ROBOT: TM5S

- KUKA: LBR iisy 6 R1300

- Mitsubishi Electric: RV-5AS-D

- FANUC Europe: CRX-5iA

- Dobot Robotics: CR5A

- Kawasaki Robotics: CL105N

- ABB Robotics: GoFa 5

- Universal Robots: UR5e

Strategic Significance for Industry

Understanding and optimising axis speed helps manufacturers strike the right balance between operational efficiency and workplace safety. Choosing the right cobot for a given application requires not only payload capacity considerations but also careful analysis of motion dynamics.

Source Attribution

Based on product specifications and industry references from leading cobot manufacturers.

Credit : vanessaloiola