The modern factory floor is no longer just a space dominated by mechanical arms and conveyor belts. It is evolving into an intelligent ecosystem, where machines can see, learn, and adapt. Powered by artificial intelligence (AI), advanced robotics, and automation, production environments are entering a new age. Here, technology does not merely execute commands — it makes decisions. This transformation represents far more than incremental progress; it signals a fundamental redefinition of industrial capabilities, promising unprecedented gains in efficiency, safety, and innovation.

At the forefront of this revolution stand global robotics pioneers such as ABB, Fanuc, KUKA, and Boston Dynamics. These companies are not only pushing mechanical limits but embedding AI-driven intelligence that reimagines what automation can achieve. Their innovations are reshaping industries once thought resistant to change — from automotive plants and logistics warehouses to energy grids and pharmaceutical facilities. Robots now leverage machine learning, predictive algorithms, and computer vision to perform tasks with superhuman precision, while continuously improving their capabilities over time.

Intelligent Machines on the Factory Floor

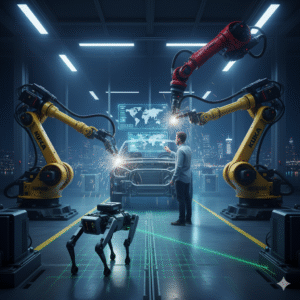

The impact of these technologies is profound. Robots can now collaborate safely with humans on assembly lines, navigate hazardous environments autonomously, and analyze massive data streams to fine-tune performance in real time. Predictive maintenance — powered by AI analytics — enables factories to address equipment issues before breakdowns occur, dramatically reducing downtime while maximizing throughput.

One of the most transformative developments is the rise of collaborative robots (cobots). Unlike traditional robots that operated in isolation, cobots are designed to work side-by-side with humans, combining the strength, speed, and accuracy of machines with human creativity and problem-solving. This synergy represents a crucial step toward building workplaces that are not just automated but intelligently augmented.

Precision and Adaptability at Scale

The rise of intelligent robotics also redefines the very nature of industrial production. Beyond efficiency, AI-driven systems offer flexibility and adaptability — allowing factories to quickly reconfigure operations to meet shifting consumer demands and global market trends. Automated lines can now pivot from mass production to customized manufacturing, ensuring agility in highly volatile markets.

Furthermore, the ability to self-optimize through continuous data learning gives these systems a lasting edge. Robots can adapt to new tasks, improve accuracy with each iteration, and anticipate future operational needs, all while maintaining rigorous safety standards. This adaptability ensures that companies remain competitive in a fast-paced economy increasingly defined by responsiveness and resilience.

Reshaping Work and Industry

This revolution is not just technological — it is deeply human. The demand for skilled workers capable of programming, maintaining, and overseeing these advanced systems is rising sharply. Far from eliminating jobs, AI-powered automation is creating new opportunities in engineering, data science, and systems management.

Governments and corporations alike recognize the role of intelligent automation in driving re-industrialization and ensuring supply chain resilience. As industries adopt smarter machines, the workforce is simultaneously evolving toward higher-value, knowledge-based roles. The factories of tomorrow will be defined not only by intelligent machines but also by the humans who design, guide, and collaborate with them.

A New Era of Global Production

The AI-powered industrial revolution is no longer a vision of the future — it is happening now. Intelligent machines are reshaping how goods are designed, produced, and delivered, turning industrial facilities into adaptive, data-driven ecosystems. The integration of AI and robotics does more than increase productivity; it unlocks possibilities for safer workplaces, sustainable growth, and entirely new business models.

As industry leaders like ABB, Fanuc, KUKA, and Boston Dynamics continue to pioneer innovation, the world is witnessing the dawn of a manufacturing paradigm where efficiency, precision, and resilience define global competitiveness. This transformation marks not just the next chapter in industrial progress but the foundation of a new era in human–machine collaboration.

Share your work with UNI Network Magazine. Upload your PDF below.

Share your work with UNI Network Magazine. Upload your PDF below.