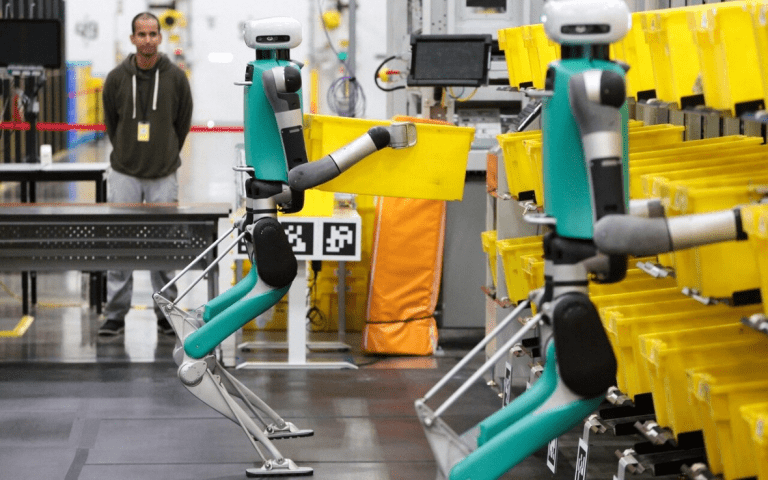

This massive deployment represents one of the largest and most advanced robotic workforces in the world, with innovations that are transforming productivity, safety, and operational speed.

According to company officials and reports from Business Insider, Amazon’s robotics infrastructure is now central to its ability to handle billions of customer orders with precision and efficiency.

Meet the Robots: Hercules, Proteus, and Sparrow

Amazon’s robotic ecosystem is built around specialized machines that each serve a unique purpose in the warehouse workflow:

- Hercules: A compact robot that lifts and transports entire shelving units across the warehouse floor. It’s optimized for heavy loads and tight navigation spaces.

- Proteus: Amazon’s first fully autonomous mobile robot designed to move safely among human workers without needing to be confined to specific zones.

- Sparrow: A highly advanced robotic arm that uses computer vision and AI to identify, pick, and sort millions of items — a major leap in automating the “pick and pack” process.

Together, these machines streamline logistics operations from inventory retrieval to last-mile preparation, significantly reducing delivery times and labor-intensive bottlenecks.

Efficiency Meets Safety

Far from replacing humans, Amazon’s robots are designed to augment human labor by taking on the most physically demanding or repetitive tasks. This shift has helped improve worker safety metrics and allows employees to focus on supervisory, problem-solving, and quality assurance roles.

In addition to increasing throughput and order accuracy, the robotics fleet has enabled Amazon to operate more sustainably, cutting energy use and minimizing product damage through precision handling.

Driving Smart Logistics at Scale

What truly sets Amazon apart is how it combines robotics with AI, machine learning, and predictive analytics to form a responsive and intelligent supply chain. Real-time data allows the system to dynamically route products, manage inventory loads, and prioritize shipments based on customer behavior and regional demand.

With fulfillment center robotics now handling up to 75% of all orders, Amazon has effectively transformed warehouse management into a tech-driven engine of scalability.

A Model for the Future

As other logistics providers and retailers race to automate, Amazon’s robotics infrastructure offers a compelling blueprint. It proves that automation, when deployed strategically, boosts both productivity and workforce potential, setting a new standard for how businesses can evolve in the digital age.

Source: Amazon Robotics & Fulfillment Press Center