Zoomlion Heavy Industry Science & Technology Co., Ltd. (1157.HK) showcased a series of transformative industrial and humanoid robotics innovations at the 2025 World Robot Conference (WRC) in Beijing, held from August 8–12. Demonstrating its dual expertise as a robot user, system integrator, and developer, Zoomlion presented new applications, breakthrough technologies, and a forward-looking strategy for the next era of intelligent manufacturing.

A Two-Decade Robotics Journey

Zoomlion’s robotics development began in 2006 with programmable industrial robots designed for large-scale, single-product manufacturing. Since 2019, the company has integrated machine vision, force sensing, and industrial internet architecture to enable agile, multimodal production.

At the Zoomlion Smart Industry City in Changsha, over 2,000 adaptive robots operate across 300 intelligent production lines, producing cranes, excavators, aerial work platforms, and concrete machinery. The facility can switch between different models in minutes, enabling highly flexible, small-batch manufacturing at scale.

Humanoid Robots Enter the Production Floor

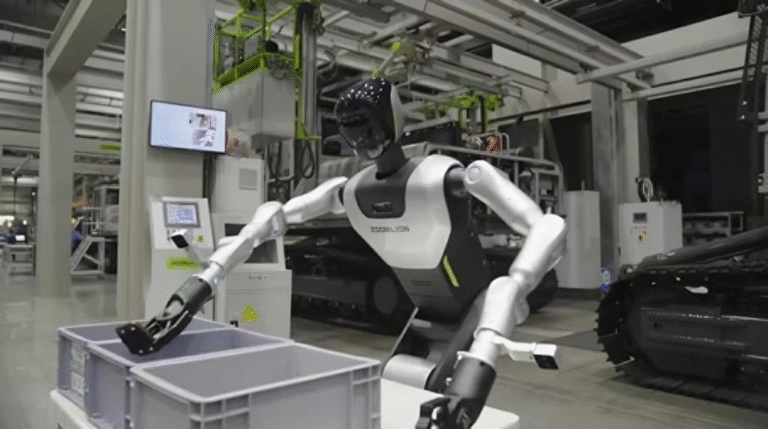

In 2024, Zoomlion expanded into humanoid robotics to address automation needs beyond the reach of traditional industrial systems. The company has developed three humanoid models — two two-wheeled and one bipedal — now deployed in pilot programs across manufacturing, logistics, assembly, and quality control.

Key capabilities include:

Key capabilities include:

-

Multimodal environment awareness with vision, force, and tactile sensing

-

Precise object grasping through sensor fusion

-

Collaborative dual-arm motion planning with built-in safety awareness

-

AI-native cloud platform for large-scale data acquisition and model training

A dedicated training facility with over 100 workstations supports rapid development and deployment of humanoid units.

Connected Intelligence at Global Scale

Zoomlion’s industrial internet platform connects 1.7 million+ units worldwide, covering 18 equipment categories and 600+ models. The system gathers over 30,000 operational parameters to create petabyte-scale industrial datasets, enabling real-time coordination and continuous improvement of robotic performance.

Vision for the Future

Zeng Guang, Managing Director of Zoomlion’s ZValley Technology Co., Ltd., emphasized a collaborative approach:

“Industrial and humanoid robots are not replacements, but partners in a new manufacturing paradigm. Our goal is to enable robots to adapt to their environment, driving manufacturing toward higher quality, greater efficiency, and improved intelligence.”

Looking forward

Zoomlion aims to integrate hardware and software development to create self-aware, self-adapting, and self-decision-making factories, where clusters of industrial and humanoid robots work in unison to maximize productivity and resilience.

Share your work with UNI Network Magazine. Upload your PDF below.

Share your work with UNI Network Magazine. Upload your PDF below.