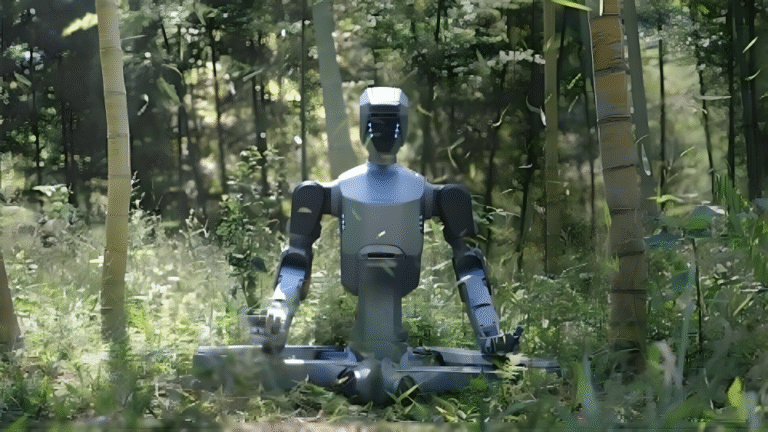

Deep Robotics has launched its latest humanoid robot, the DR02, claiming it as the world’s first industrial-grade humanoid designed for all-weather outdoor use. Unveiled on October 9, the second-generation robot brings enhanced durability, mobility, and industrial functionality to environments that were previously challenging for humanoid robots.

All-Weather Design and Durability

The DR02 boasts an IP66 rating, making it resistant to dust and water. It is engineered to operate in extreme temperatures ranging from -20°C to 55°C, enabling deployments in rain, high humidity, cold storage, and high-temperature industrial workshops. These features make it suitable for outdoor patrols, factory operations, and other variable climate conditions.

Mobility and Load Handling

Standing 175 cm tall with adult-like proportions, the DR02 walks at 1.5 m/s under normal conditions and can accelerate to 4 m/s in emergency scenarios. It can climb stairs up to 20 cm, navigate slopes of up to 20 degrees, and carry loads of up to 20 kg, with each arm handling 10 kg. This enables practical applications such as cargo handling, equipment delivery, and industrial support tasks.

Modular Design and Advanced Computing

To optimize maintenance, the DR02 features a modular quick-detach design, allowing critical components like arms and legs to be easily replaced, minimizing downtime and operational costs. The robot is powered by a 275 TOPS computing unit, facilitating real-time task management, obstacle avoidance, and path planning. A multi-sensor suite, including LiDAR, depth cameras, and wide-angle cameras, enables comprehensive perception of its surroundings.

Industrial Applications and Market Potential

Deep Robotics positions the DR02 as a solution to the longstanding challenge of humanoid robots performing reliably outdoors and under harsh conditions. Potential applications include security, manufacturing, logistics, infrastructure maintenance, and other industries that require robust, autonomous humanoid operations.

The company aims to address gaps in industrial robotics by enabling humanoid robots to extend beyond controlled factory floors into real-world environments, bridging a crucial technological divide in the sector.